Enhancing Accuracy in Grinding and Sawing: Optimize your Crystal Processing

Freiberg Instruments sets new standards in crystal growth and processing with state-of-the-art metrology solutions. Our advanced tools ensure precise alignment of high-mobility crystal directions with transistor channel orientations, enabling peak performance in semiconductor and material fabrication industries.

Key Advantages

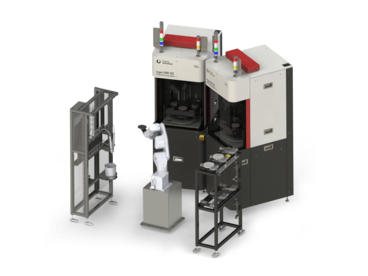

Tailored to your workflow

Every fab is unique, like a living organism. Our tools are meticulously designed to seamlessly integrate into your material workflows and data processing systems.

Highest precision

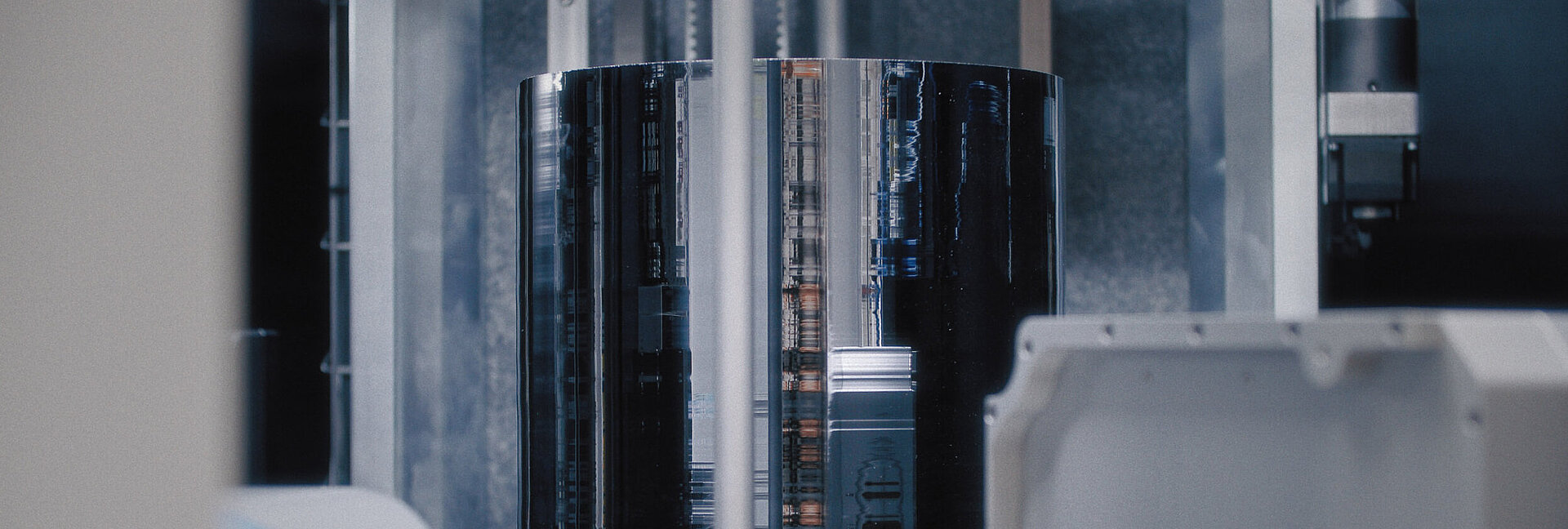

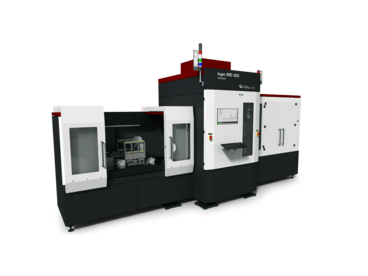

Our method stands unrivalled in combining precision, speed, and 3D crystal orientation. Leveraging our proprietary algorithms, we calculate the optimal cylinder and empower cost-efficient process tools with a single Ingot XRD solution.

Comprehensive seed-to-wafer solution framework

We provide tailored solutions for every stage of oriented crystal manufacturing, offering a wide range of customized options to meet market demands. Bring us your toughest process challenges – we're ready to deliver!

Onsite service and training

Reduce your total cost of ownership by participating in our on-site training program! We empower you to perform first- and second-line servicing on your tools, ensuring maximum uptime and full control over your process – no matter your location or access limitations.

Precision in Every Step

Expertise in Materials

Future-Proof Your Manufacturing Process

As industry demands evolve, so do our solutions. Freiberg Instruments remains at the forefront of innovation, helping clients optimize efficiency, investigate defects, and maintain a competitive edge in crystal growth and processing.

Get in touch

Do not hesitate to contact us – we are available to assist you with any inquiries or requests.

Use our inquiry tool or reach out via email:

sales@freiberginstruments.com