Established Omega-scan method

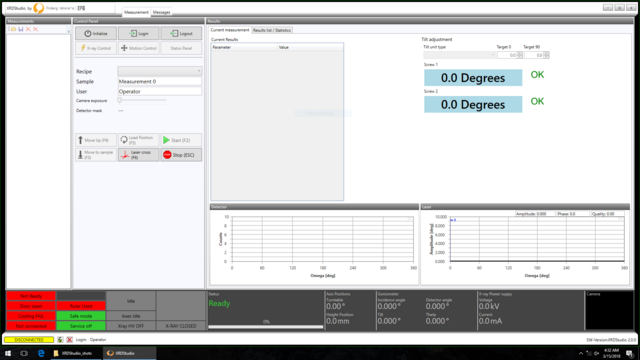

All measurements are automated and can be accessed from the user-friendly software interface

Using the Omega Scan, the complete lattice orientation can be determined in on crystal rotation (5 seconds)

The Theta Scan is more flexible, but results only in one orientation component per scan

Materials

Our Omega/Theta XRD systems enable precise analysis across a wide range of materials. Designed for flexibility and exceptional performance, they effortlessly meet the most demanding industry requirements.

Features & Benefits

< 5 s/sample

Measurement speed

Up to

450 mm

Sample size

0.1 arc sec

Angular resolution of the diffractometer

Ultra-fast

crystal orientation measurement