Advanced R&D – destruction free, flexible and fast

Highly sensitive due to advanced microwave system

Customized laser and optic integration for all your materials

Simultaneous resistivity measurement and other options

Materials

The MDPmap features a versatile selection of advanced lasers, enabling comprehensive electrical characterization for nearly all types of semiconductors.

Features & Benefits

355–1550 nm

Available wavelengths

10 ns

Time resolution

> 99 %

repeatability

Resistivity

0.3–5

Ohm cm

Resistivity

0.3–5

Ohm cm

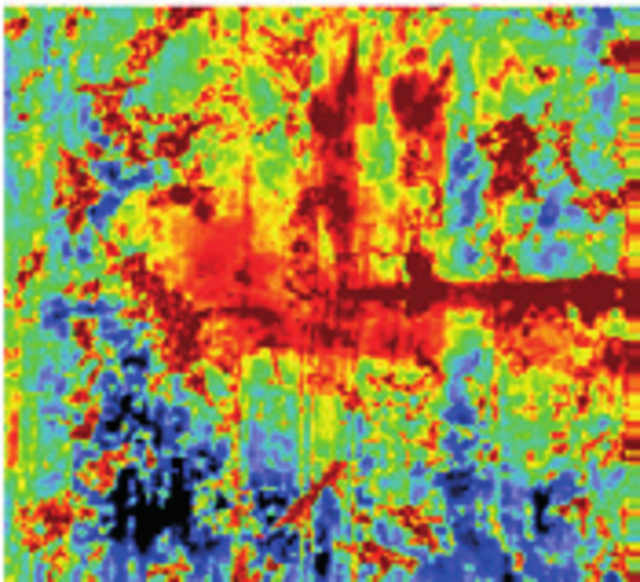

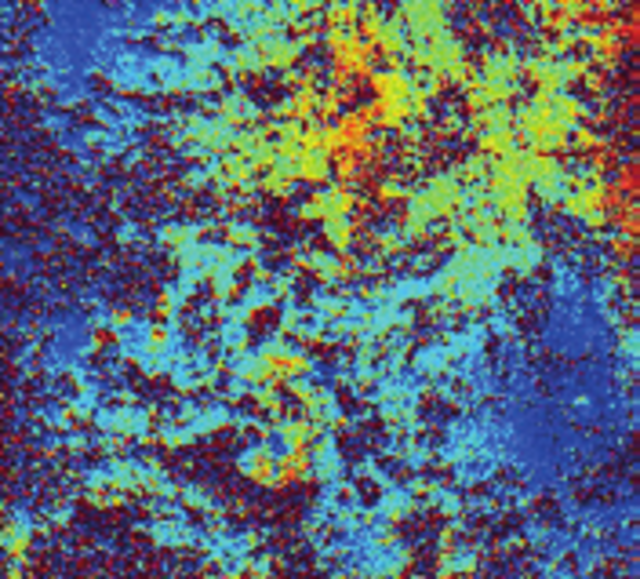

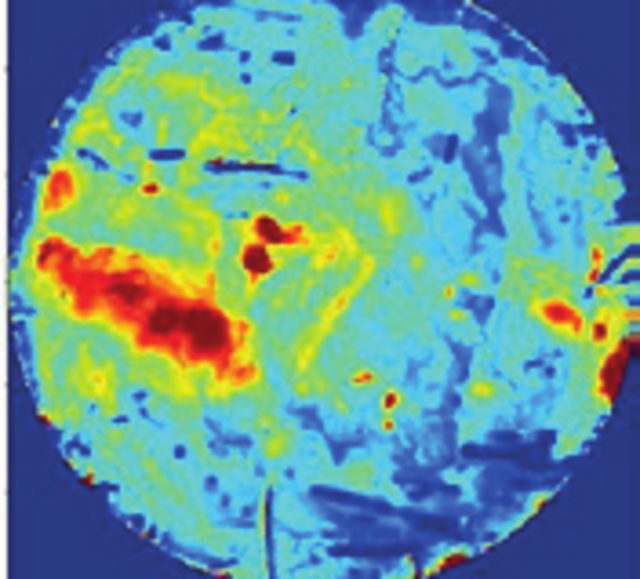

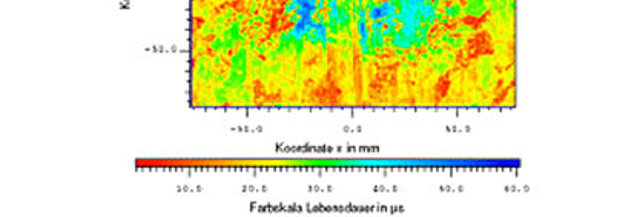

Sensitivity: highest sensitivity for visualization of so far invisible defects and investigations of epitaxial layers

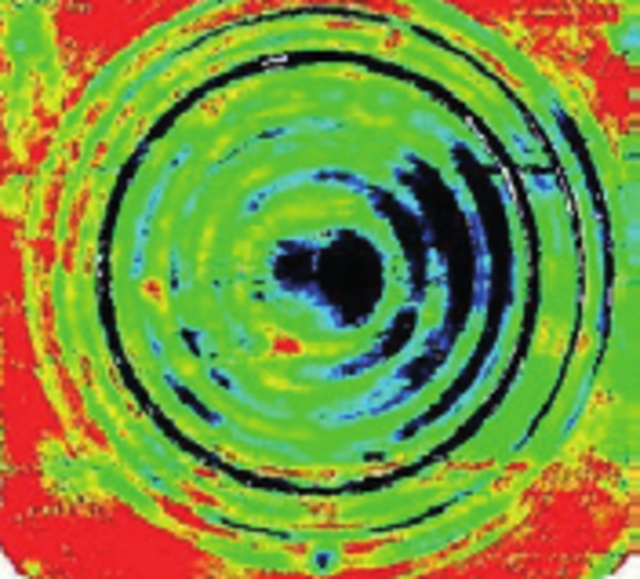

Measurement speed: < 5 minutes for a 6 inch Si wafer, 1 mm resolution

Range of lifetimes: 20 ns to several ms

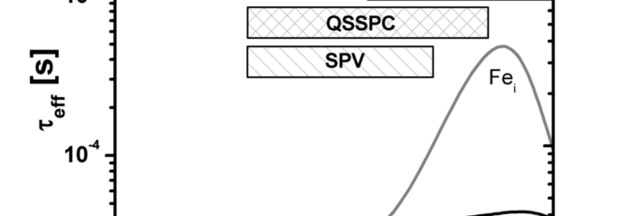

Contamination determination: metal (Fe) contaminations originated in crucibles and equipment

Measurement capability: from as-cut wafers to fully processed samples

Flexibility: fixed measurement head allows coupling of external lasers with trigger

Reliability: modular and compact bench top instrument for higher reliability and uptime > 99%

Repeatability: > 99%

Resistivity: resistivity mapping without frequent calibration

Flexible mapping tool for R&D or production monitoring

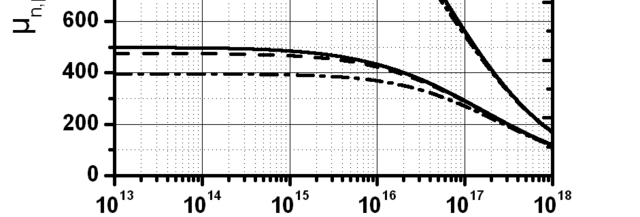

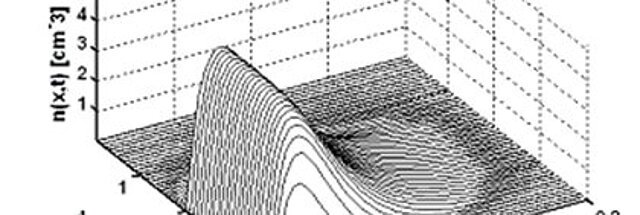

MDPmap is designed as a compact bench top contactless electrical characterization tool for offline production control or R&D, measuring parameters like carrier lifetime, photoconductivity, resistivity and defect information over a wide injection range in steady state or short pulse excitation (μ-PCD). Automated sample recognition and parameter setup allows an easy adaption to a big variety of different samples comprising epitaxial layers and wafers after various preparation stages ranging from as-grown wafers to up to 95% metallized ones.

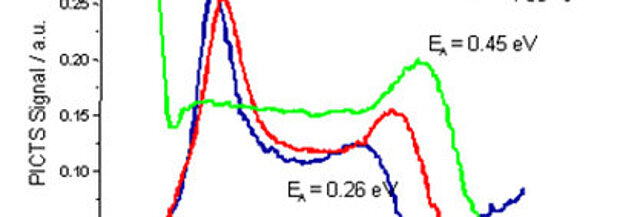

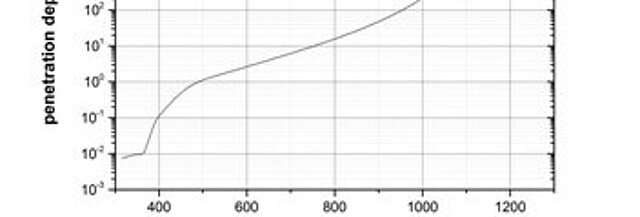

The major advantage of MDPmap is its high flexibility, which allows for instance the integration of up to four lasers either for injection level dependent lifetime measurements ranging from ultra low to high injection or extracting depth information by using different laser wavelengths. Bias light facility is included as well as options for μ-PCD or steady state injection conditions. A customer defined calculation with different maps is possible as well as an export of primary data for further evaluation. For standard metrology tasks a predefined standard enables routine measurements by only pushing one button.

Applications

Technical specifications

| sample size | up to 300 mm diameter (standard), up to 450 mm diameter (on request), down to 5 x 5 mm |

|---|---|

| range of lifetimes | 20 ns to several ms |

| resistivity | 0.2 - >103 Ohm cm, p/n |

| material | silicon wafer, epi layers, partially or fully processed wafers, compound semiconductors and beyond |

| measureable properties | lifetime - μ-PCD/MDP (QSS), photoconductivity |

| excitation | select up to four different wavelengths from 355 nm up to 1480 nm. 980 nm (default) |

| dimensions | 680 x 380 x 450 mm, weight: ca. 65 kg |

| power | 100 - 250V, 50/60 Hz, 5 A |

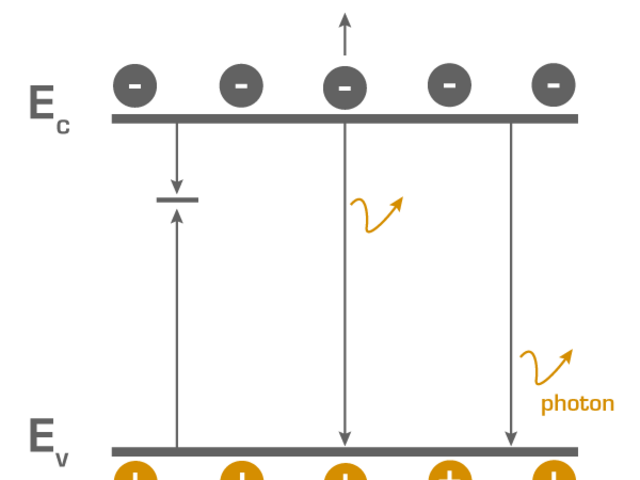

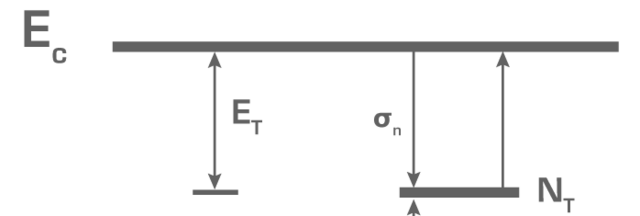

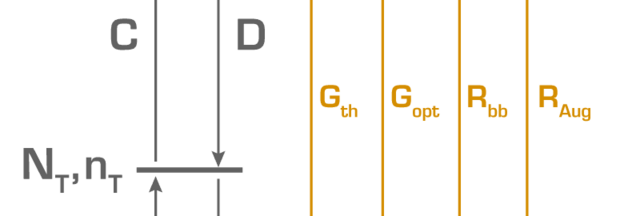

Technologies

Accessories & Options

Our devices offer versatile configuration options to meet specific requirements effectively. Each model can be customized to ensure maximum flexibility and efficiency.

Spot size variation

Resistivity measurement (wafers)

Sheet resistance

Background/Bias light

Reflection measurement (MDP)

LBIC for solar cells

Reference wafer

Internal/External iron mapping of Si

Integrated heating stage

Wide range of lasers

Get in touch

Do not hesitate to contact us – we are available to assist you with any inquiries or requests.

Use our inquiry tool or reach out via email:

sales@freiberginstruments.com