Potential Induced Degradation (PID) is a significant reliability issue in photovoltaic (PV) power plants. It is crucial to assess the susceptibility of products to PID early in the production process. The PIDcon system is designed to help manufacturers test their products and evaluate encapsulation materials at the earliest possible stage in the production chain.

PIDcon enables routine quality control for standard production cells, testing of new processes, material or layer variations, and qualification for various module production steps. The PID being referred to here involves shunting of solar cells caused by high-voltage stress-induced leakage currents (PID-s).

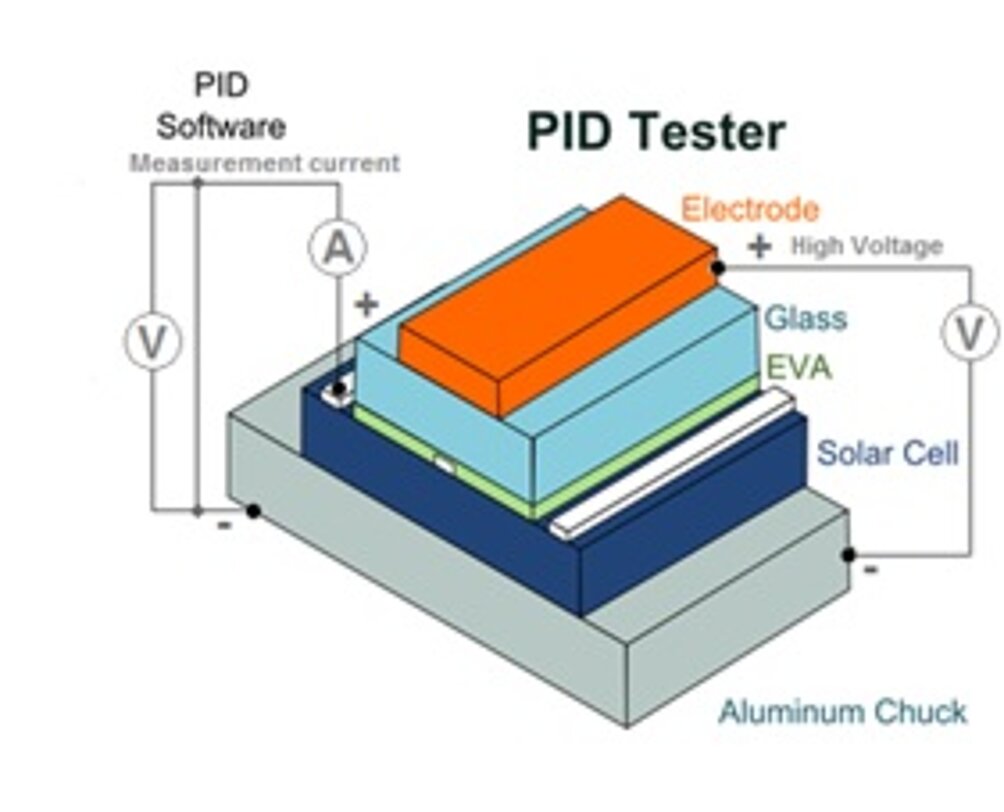

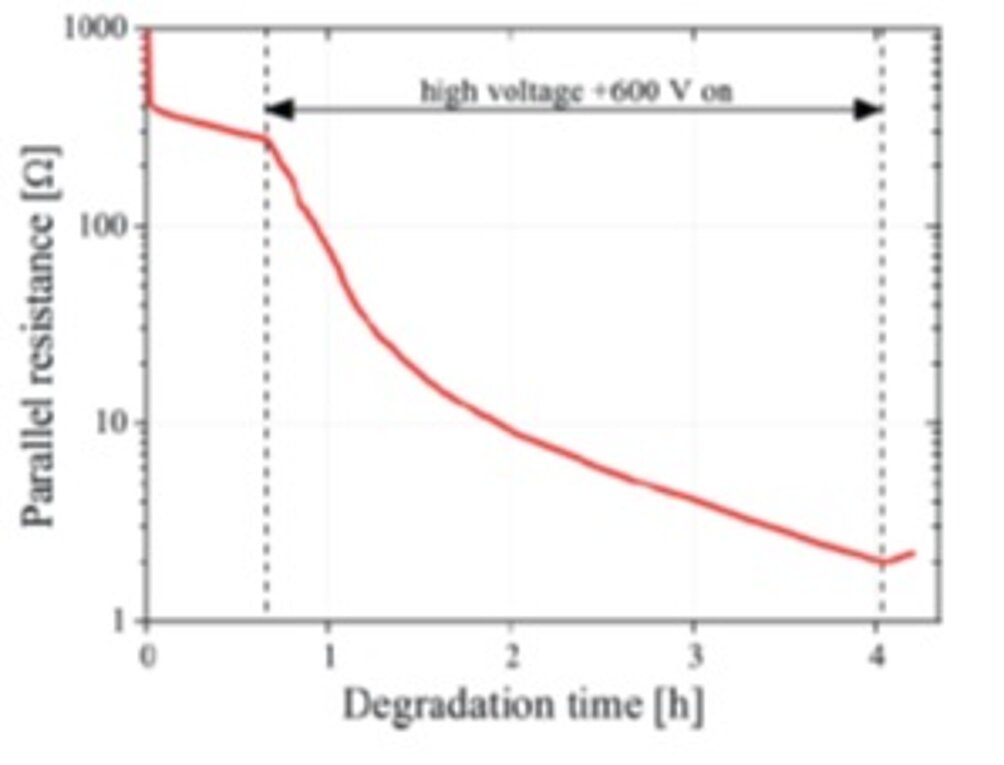

The PIDcon's construction is nearly identical to the IEC standard (see figure 1). The sample stack, consisting of a solar cell, EVA foil, and glass, simulates a solar module. This method allows for the testing of both solar cells and encapsulation materials. Figure 2 illustrates a typical PIDcon measurement of a PID-sensitive solar cell.

Key Advantages of PIDcon Over Conventional Module Testing

No Climate Chamber Needed

Early Measurement in the Production Chain

Suitable for Both Research and Routine Production Quality Control

Short Testing Duration (typically 4 to 8 hours)

Measurement and Recording of Shunt Resistance with Estimation of Power Loss

Matching Products

Get in touch

Do not hesitate to contact us – we are available to assist you with any inquiries or requests.

Use our inquiry tool or reach out via email:

sales@freiberginstruments.com