Bar Alignment, Wafer Analysis & Blank Sorting using X-Ray Diffractometer

Measurement speed as low as 2 s (AT quartz)

Highest precision ≤ 10 arcsec standard deviation

Spatial resolution 1 mm ± 0.1 mm

Features & Benefits

The Quartz XRD series

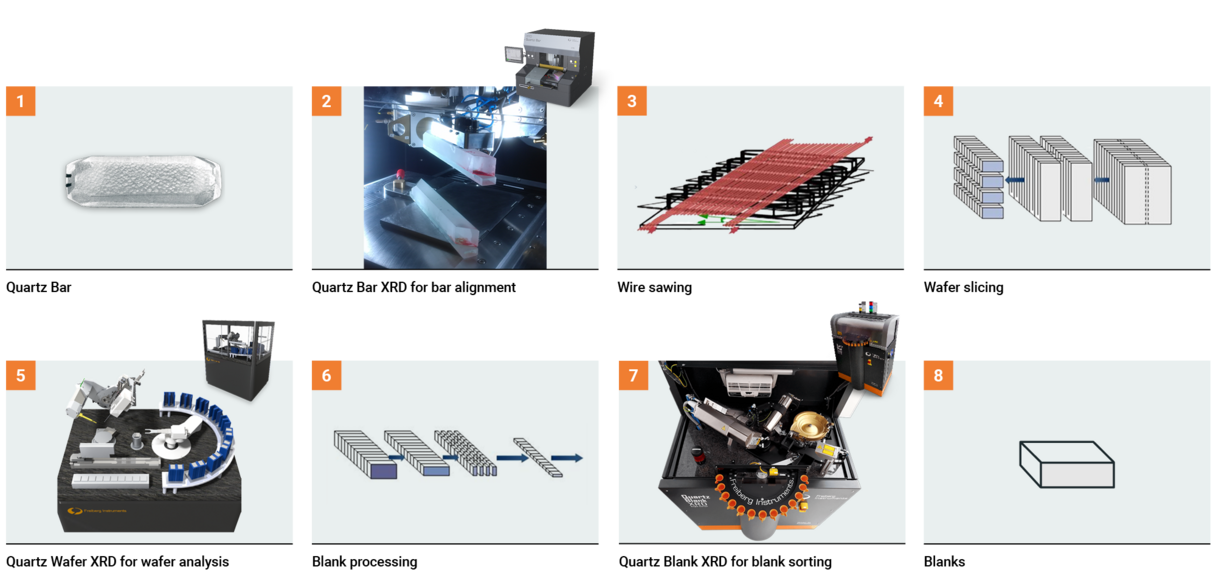

Manufacturing Process from Bar to Blank

We’ve built XRD systems for the quartz industry for decades – some run 24/7 after 20+ years. That stability delivers consistent, traceable results every shift.

Dr. Ing. Hans-Arthur Bradaczek

Head of X-ray Technology