Achieving goals together: Projects with measurable added value

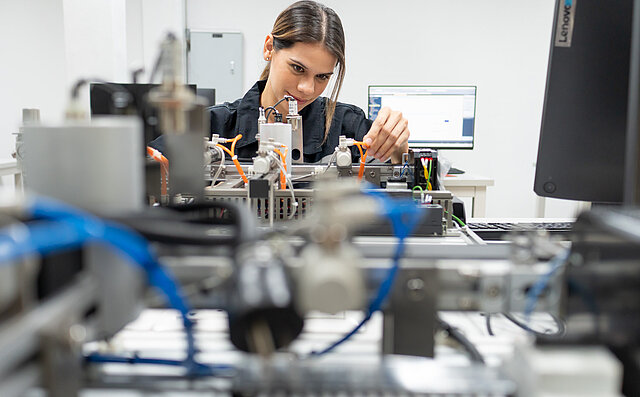

Freiberg Instruments stands for the highest precision and groundbreaking technologies in materials research and measurement technology. Our projects impressively demonstrate how versatile and adaptable our solutions are – from collaboration with renowned research institutions to complex industrial applications.

We rely on innovative approaches, tailor-made technologies and a close partnership with our customers. Whether it is about supporting groundbreaking research or increasing efficiency in production – our projects are proof of our expertise and our commitment to the highest standards.