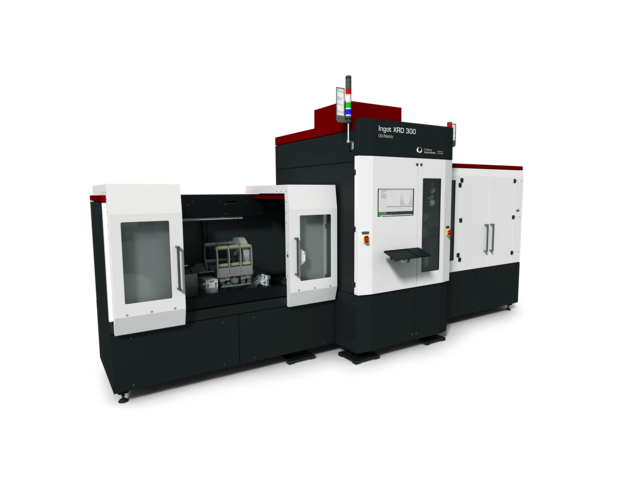

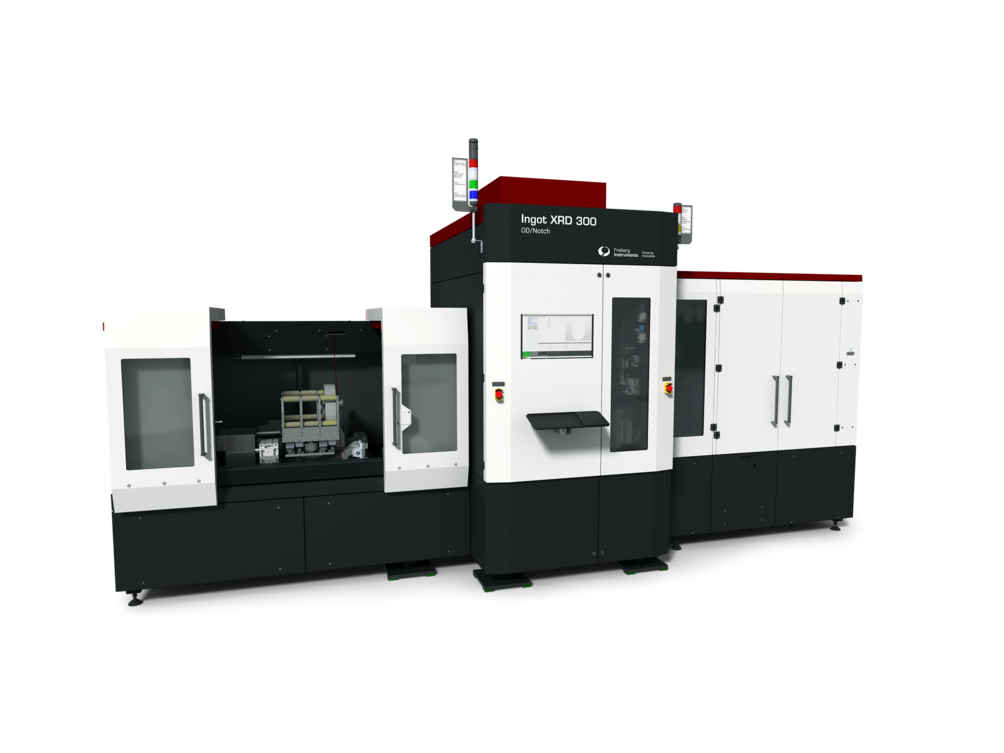

Rethink your ingot grinding preparation: automated, precise, fast.

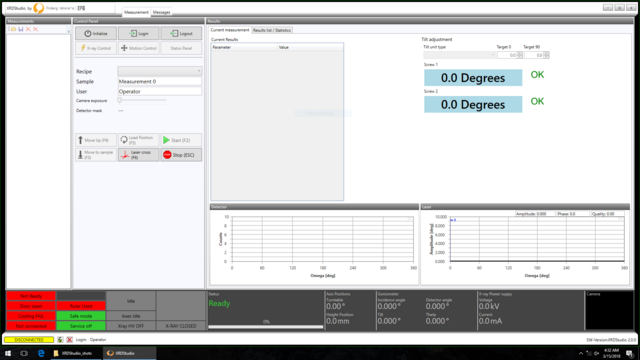

Rapid determination of crystal orientation

Optical geometry inspection with integrated confocal sensor

Accurate and fully automated gluing and end piece attachment

Features & Benefits

70–300 mm

Ingot size

0.005°

On-axis precision

Flexible

Loading and communication options

Cylinder

Calculation

with hybrid metrology