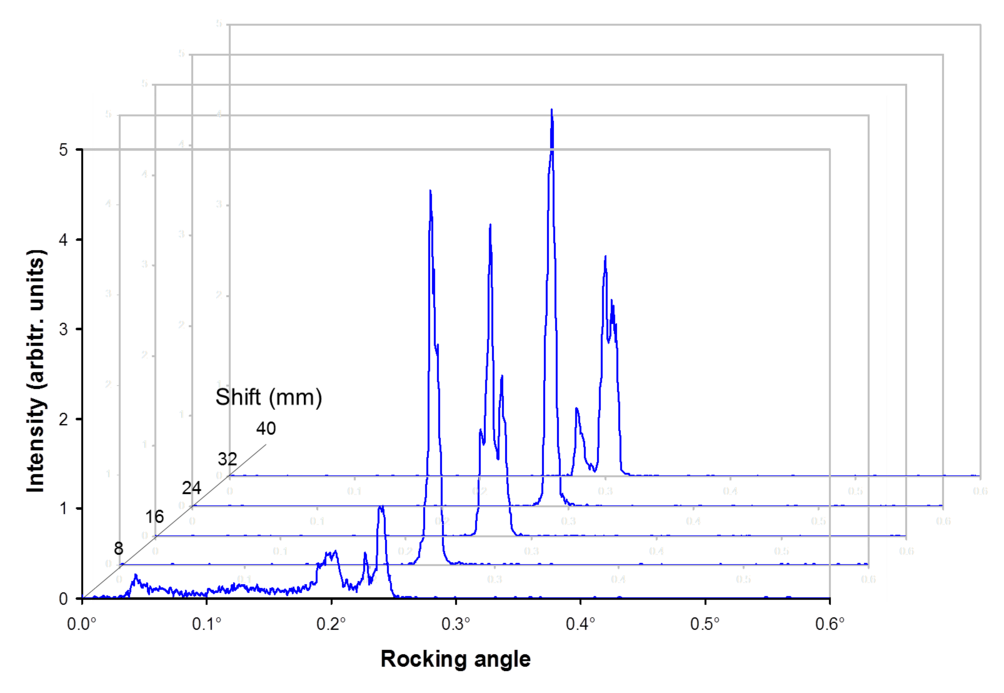

The Rocking Curve of a crystal reflection indicates the quality of the crystalline lattice. This can be down pointwise for fast checking or in combination with a mapping tool to receive a quality map.

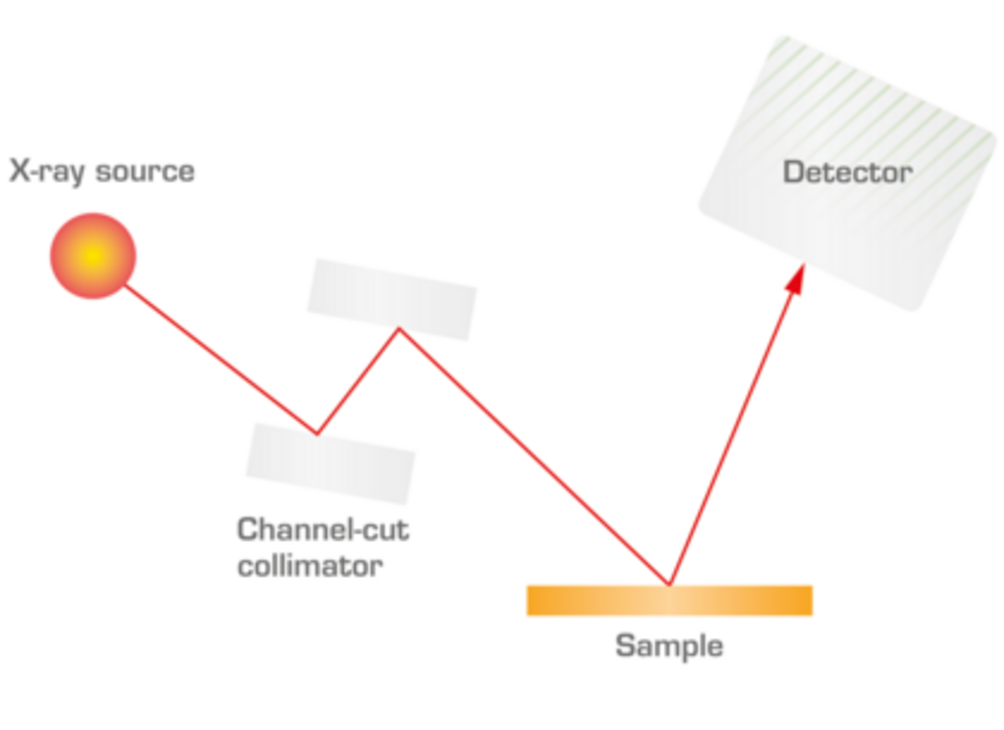

Measuring a Rocking Curve means measuring in Theta-scan mode, which requires a goniometer. A double crystal is brought into the primary beam path to decrease the spectral width and divergency. However, the side effect is a strongly reduced intensity. Therefore, the double crystal is mounted on a retractable holder to be able to switch it "on" or "off".