Aim

Polymers and semiconductors are highly functional materials, and major components of electronic and electrical products. Their detailed characteristics are key to validate functionality and ensure adequate treatments both in manufacturing and post-consumer management stages of their life cycle. An automated, contact-free and non-destructive sensing solution can provide the framework for real-time industrial operations, as needed in various applications in the fields of production and waste management (i.e. recycling).

Solution

Raman spectroscopy measurements provide a powerful solution for detecting the detailed composition of both polymers and semiconductor materials.

For polymers, Raman spectra contain the information needed to identify not only key polymer types (e.g. PE, PP, ABS, PS, PC, PET, PVC, PMMA), but to also overcome the challenging identification of black polymers, additives and polymer blends relevant for high quality sorting, recycling and quality control. For semiconductors, information from Raman measurements can detect the type of semiconductor (e.g. Si, Si-C, Sapphire), including the presence and type of dopants. Short integration times, combined with the possibility of robotic integration, allow for agile sensing solutions in dynamic settings such as on top of conveyor belts.

The main advantages of our Raman measurement head are:

Selection of different laser powers + integration times allow for Identification of several material streams which are unresolved by current solutions (challenging complex polymers, Identification of semiconductor type and presence/type of dopants).

Possibility of sensor integration to robotic arms with automatic shutter and interlock signal for security

Possibility of robot-based operation in a sensor network for high-throughput advanced classification of complex materials (linked to invention disclosure and patent application).

software interface for selecting ‘recipes’ of different laser power/integration times according to each stream

Application example

Raman measurements have been conducted in the dynamic setting of conveyor belt-based material stream characterization. Under ambient light conditions, the diagnostic fingerprints of major polymer types could be recorded down to 0,5 s integration time with an adequate signal to noise ratio which allows for their identification (see Fig. …). Laser power can be tuned according to the needs of selected material types, ensuring optimal signal acquisition for multiple material streams. For more comprehensive material stream characterization, it is possible to integrate the robot-compatible Raman sensor with further imaging sensors (e.g. RGB and reflectance-based hyperspectral cameras). In such a complex, integrated system, a robot-mounted Raman solution provides a myriad of tailor-based options for boosting the accuracy of results and widens the range of detectable materials.

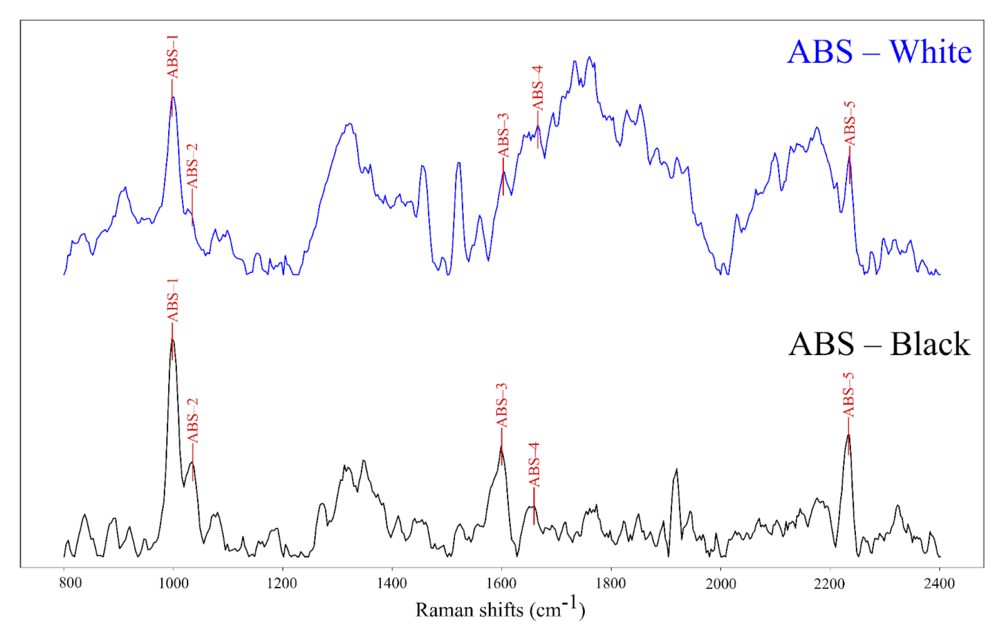

Fig 1. Raman spectra collected from ABS-white (top) and ABS-black (bottom) plastic standards. Acquisition times from 250–500 ms.

Identification of ABS is key in electronic waste recycling, as the material shares spectral features with other styrenic polymers in VNIR-SWIR (sensor most commonly used in the plastic recycling industry). Particularly, allows for the differentiation between ABS and PS polymers.

Identification of polymer fingerprints from signals acquired at fast acquisition times (maximum: 500 ms).

Successful use of recipes for signal acquisition of samples of the same plastic type, but with different colours (white-ABS vs black-ABS).

Acquisition of polymer-specific features in samples with white pigments and broad fluorescence bands (from 1600–2000 cm-1) -> ABS white

Acquisition of polymer-specific features in samples with black pigments and high absorption of excitation light, without damaging the material -> ABS black (500 ms acquisition time).

Highlight: measurement conditions suitable for real-time and dynamic settings short integration time and tunable laser power

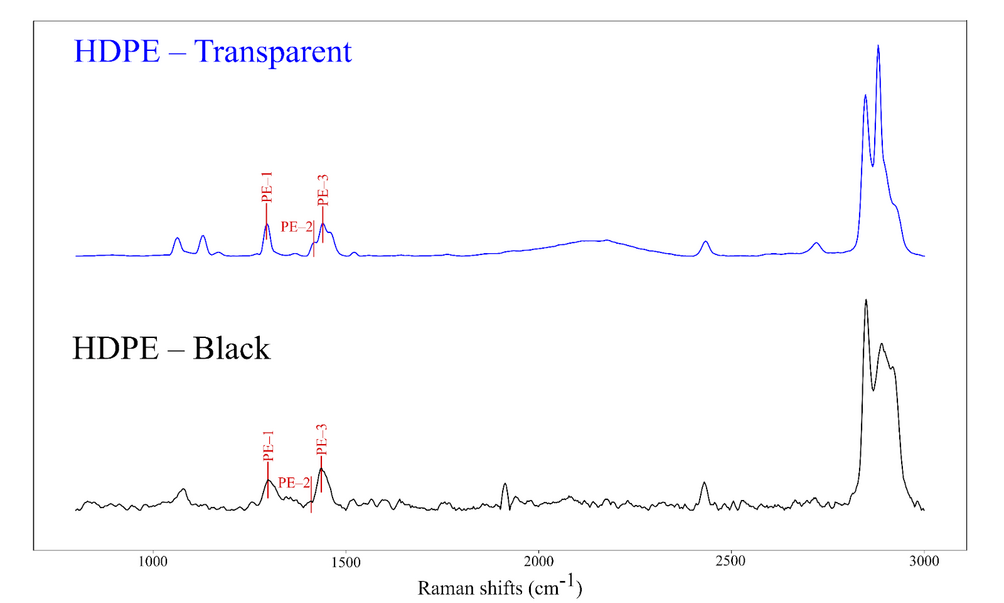

Fig. 2. Raman spectra collected from HDPE-transparent (top) and HDPE-black (bottom) plastic standards. Acquisition time: 500 ms.

Identification of diagnostic HDPE-diagnostic features in both transparent and black standards.

HPDE transparent: no influence from the background materials are observed in the final spectra (this means that the presence of a conveyor belt or another dark-colour background doesn’t impact the signal collection.

HDPE black: depending on the amount of dark pigments and other absorbers, signal acquisition may be impacted (see low SNR for PE-2 feature). Still, the other PE-related fingerprints exhibited good SNR, which allow for identification of the polymer type even under limiting conditions.

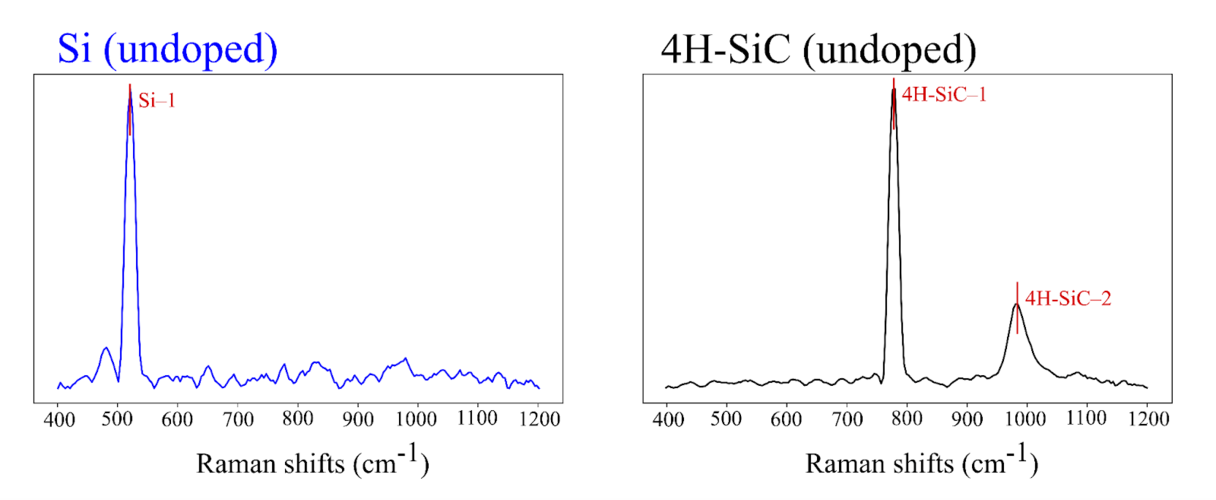

Example for identification of semiconductor type (Si and 4H-SiC) using the RAMSES measurement head.

Matching Products

Get in touch

Do not hesitate to contact us – we are available to assist you with any inquiries or requests.

Use our inquiry tool or reach out via email:

sales@freiberginstruments.com