Features & Benefits

Inline line scanner or single spot measurement

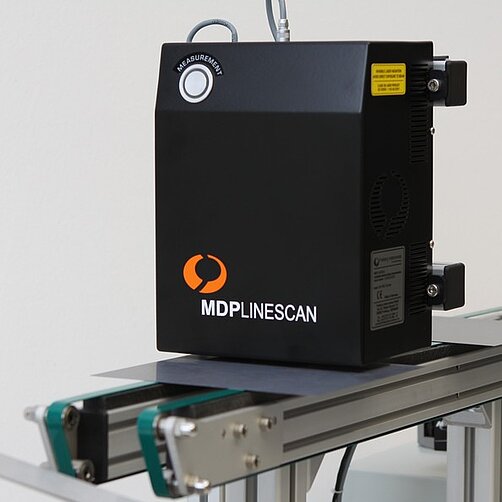

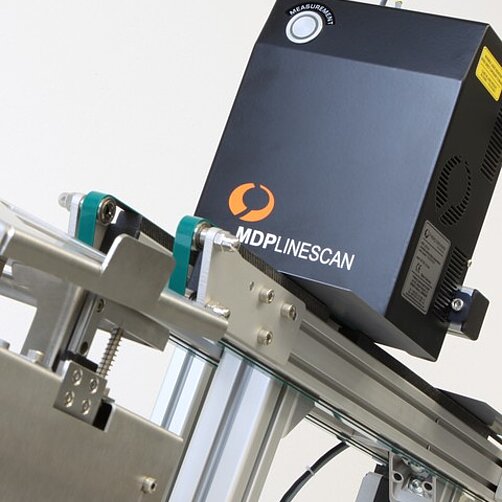

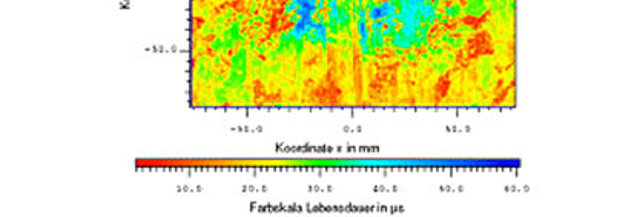

The MDPlinescan is an OEM unit designed for seamless integration into automated inspection systems. It performs carrier lifetime scans in real-time, typically with samples transported beneath the measurement head by a conveyor belt or robotic system. Applications span from silicon brick to wafer inspection, achieving measurement speeds of under one second per wafer. It is widely used for assessing incoming material quality in cell production lines and for process quality checks after passivation and diffusion, among other specialized applications. Integration is straightforward, requiring only an Ethernet connection and power supply.

Facts

allows for single wafer investigation

recipe based measurements

monitoring of material quality, process integrity and stability

Advantages

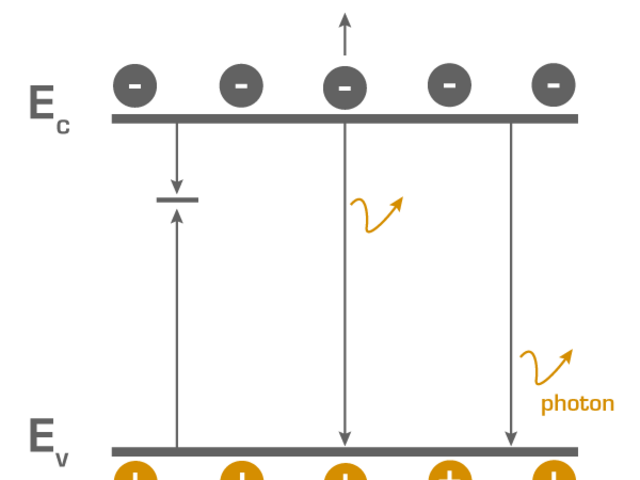

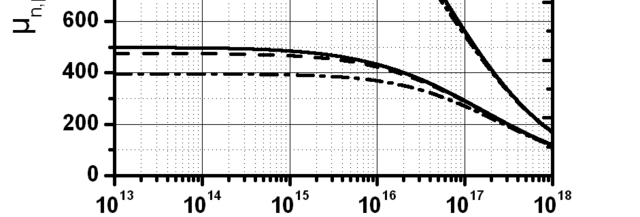

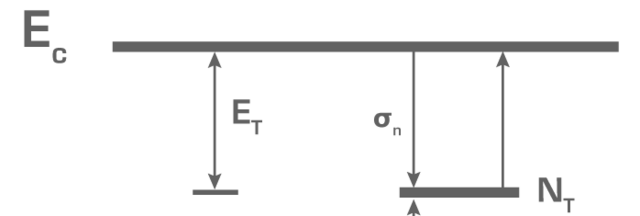

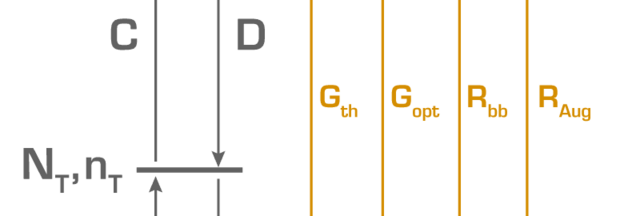

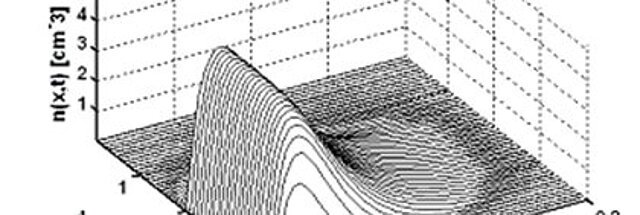

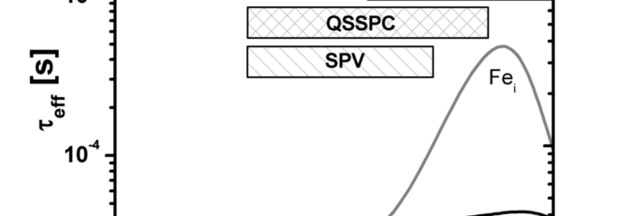

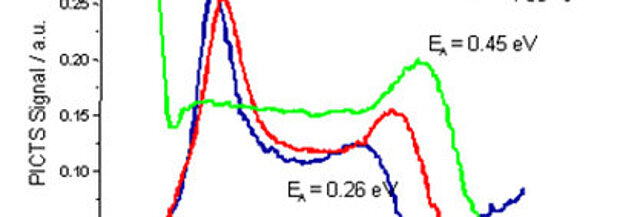

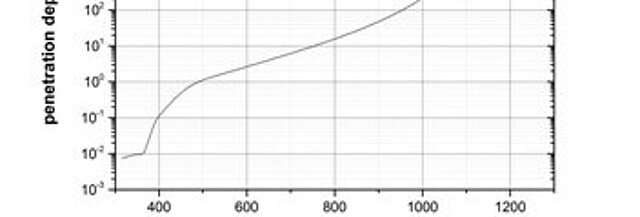

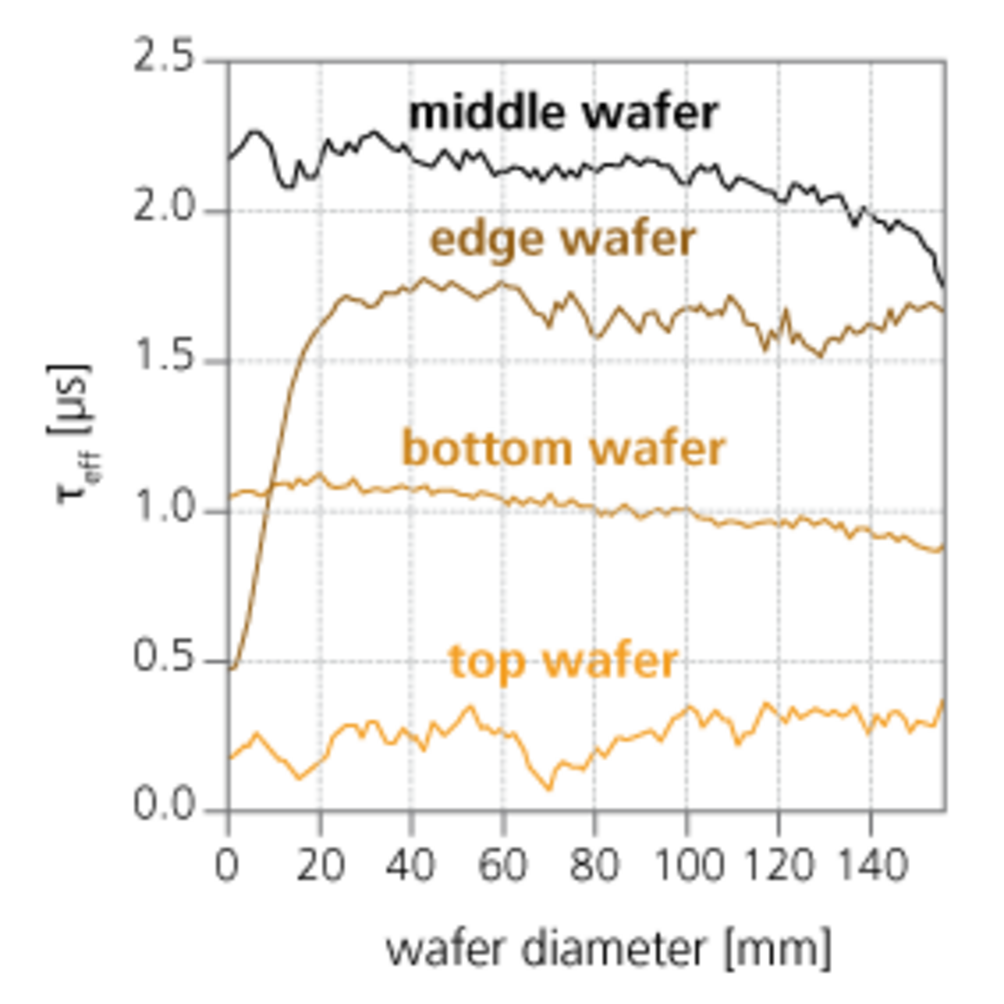

Measurement of minority carrier lifetime and resistivity lines cans at µ-PCD or steady state excitation conditions are in the focus of this small tool.

OEM unit for the integration in production lines for multi- or monocrystalline silicon wafers at different preparation stages up to devices, bricks or ingots.

Small size and standard automation interfaces allows for easy integration. Focus is put on long reliability and precision of measurement results.

Applications

| sample | raw multi or mono wafers of multiple sizes like 156 mm², bricks, cells |

|---|---|

| sample size | above 50 x 50 mm² |

| resistivity | 0.2 - 10³ Ohm cm |

| conduction type | p, n |

| material | silicon wafers, partially or fully processed wafers, compound semiconductors and beyond |

| measurable properties | carrier lifetime |

| hardware interface | ethernet |

| dimension | 174 x 107 x 205 mm, weight: 3 kg |

| power | 24 V DC, 2 A |

Technologies

Get in touch

Do not hesitate to contact us – we are available to assist you with any inquiries or requests.

Use our inquiry tool or reach out via email:

sales@freiberginstruments.com