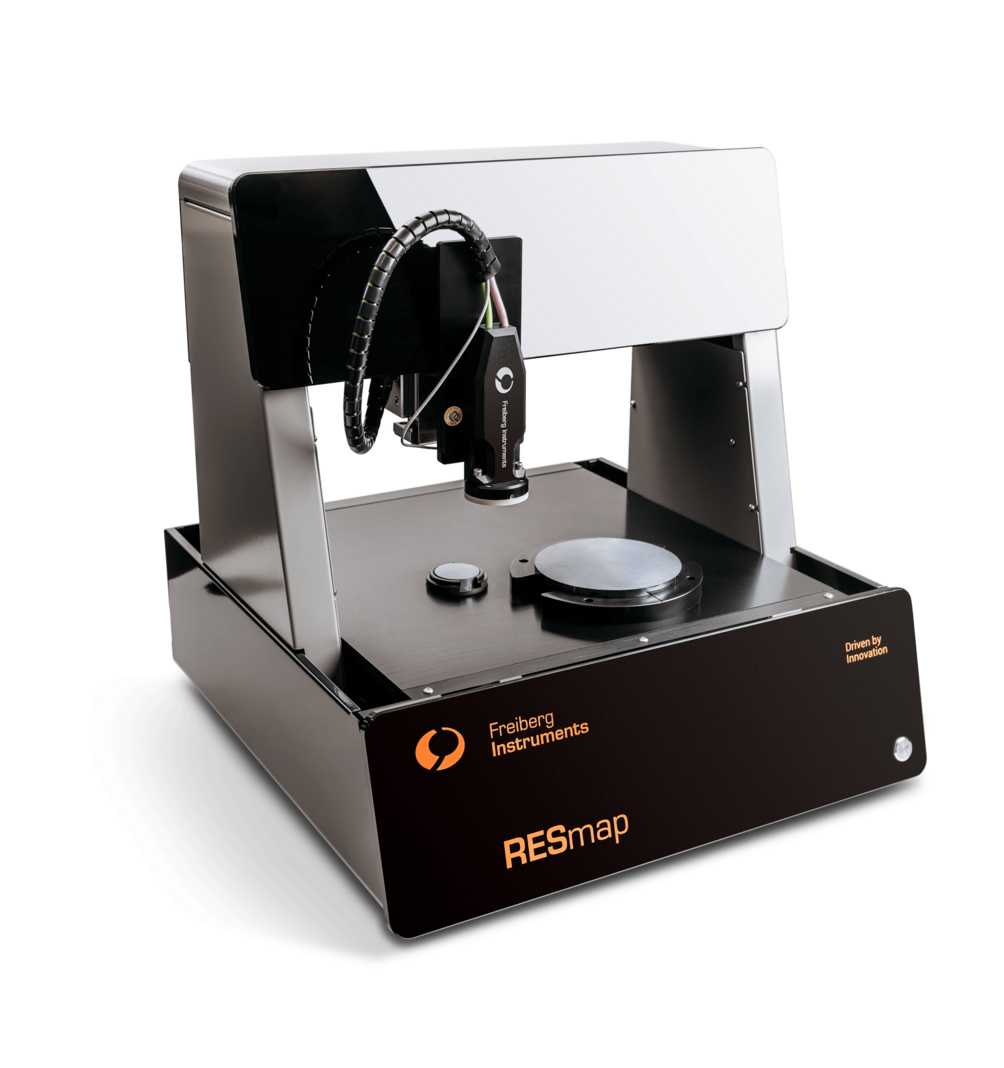

Fast and reliable resistivity mapping tool for highly doped samples

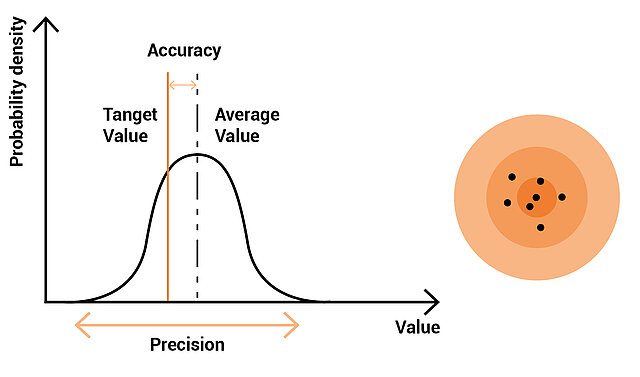

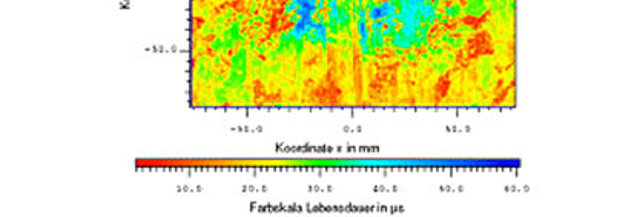

Exceptional Repeatability (sigma < 0.15%)

Advanced Stability Sensors

Seamless Inline Integration and Effortless Calibration

Materials

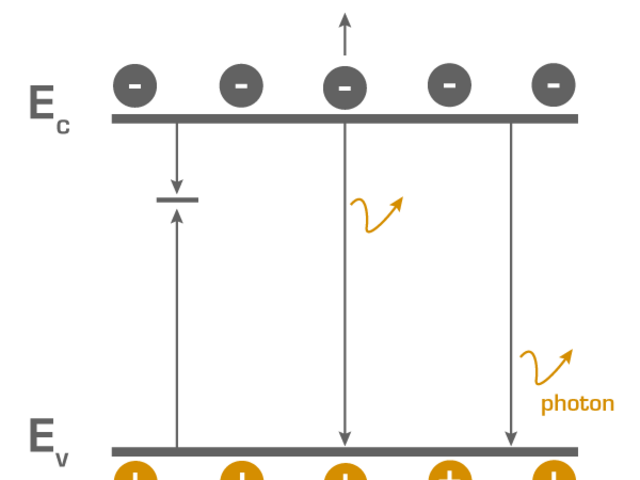

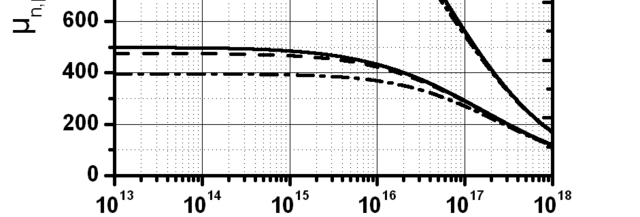

The RESmap is specialized on highly doped materials

Applications

RESmap delivers unmatched repeatability, stability and accuracy – making it the trusted choice for precise resistivity mapping across a wide range of materials.

Dr. Christian Hagendorf

Key Account Manager

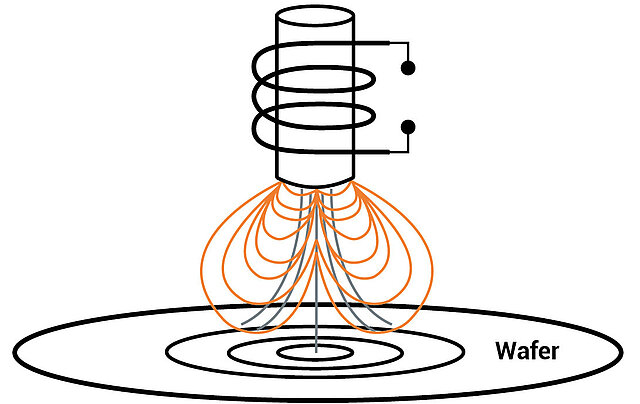

Technologies

User-friendly and advanced operating software with

Resistivity measurement recipes

Export/import functions and raw data access

Multi-level user account management

Overview over all performed measurements

Mapping options (line, cross, star, full map, topography, user defined pattern)

Package of analysis functions; statistics, variance analysis, temperature correction functions and library

Remote accessibility; Internet based based system allows remote operation and technical support from anywhere in the world